Green Hydrogen Transformation Project

Location: Duisburg, Germany

Location: Duisburg, Germany

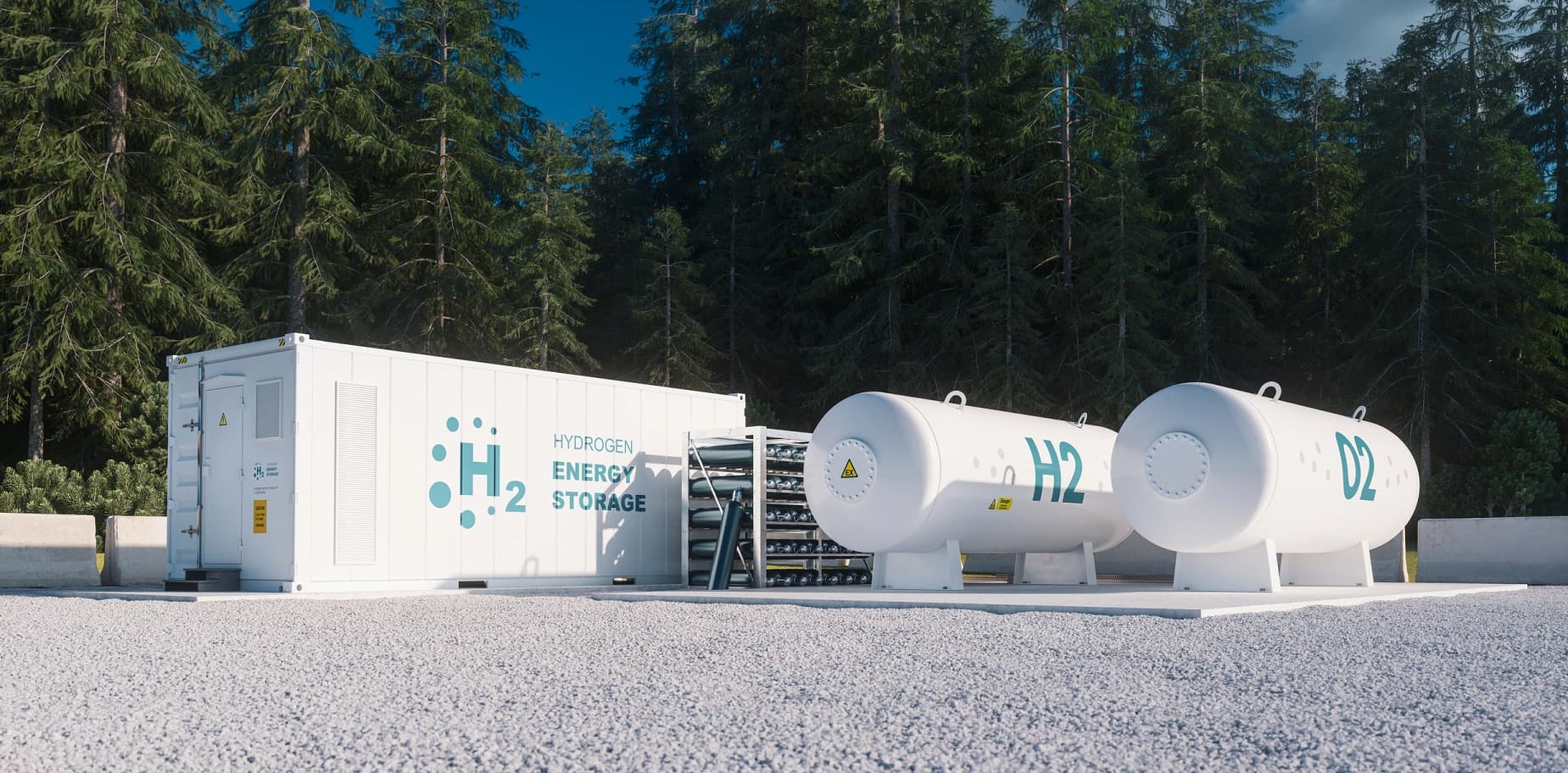

The hydrogen required for iron production is to be produced by electrolysis, in which water is broken down into hydrogen and oxygen. Only electricity from renewable sources will be used to operate the electrolyzers. Our client's power plant site in Lingen is already planning to build electrolysis capacities that could supply green hydrogen for their iron production.

A 100 MW electrolyzer could produce 1.7 tons of gaseous hydrogen per hour, corresponding to around 70 percent of the quantity required by the Duisburg steelmaker’s blast furnace earmarked for hydrogen use. This would translate theoretically into around 50,000 tons of climate-neutral steel. The conversion of the blast furnace is to be carried out by 2022.

Work Scope

Green hydrogen is being produced from an electrolyzer to help our client sustainably reduce CO2 emissions from steel production in the future. The energy company and the steel producer have agreed to work together towards a longer-term hydrogen partnership. The first hydrogen is set to flow to the Duisburg steel mill by the middle of the decade. CO2 emissions from iron production will be reduced, and the 100 MW electrolyzer could cover 70% of the H2 requirements of our client's blast furnace. The rapid implementation of National Hydrogen Strategy is helpful for investment decisions.

Brunel project team

Brunel was awarded the contract to provide process engineering support services for:

✔ Contact Brunel Renewable Energy Today

✔ Renewable Energy Recruitment and Workforce Services

✔ Global Renewable Energy Jobs